Stainless steel material is a very common steel that is often used in the machining industry. It is often used to make various parts or components for automation equipment/packaging equipment/food processing equipment/medical equipment( instrument), etc., as well as various daily necessities.

When brown rust spots appeared on the surface of stainless steel materials, people were surprised: "Stainless steel is not rusty. If it rusts, it is not stainless steel. It may be that the quality of the steel has a problem." In fact, this is a one-sided wrong view of the lack of knowledge of stainless steel. Stainless steel can also rust under certain conditions.

Stainless steel has the ability to resist being oxidized by the atmosphere---that is, it is not rusty, and it also has the ability to resist corrosion in media containing acid, alkali and salt---that is, corrosion resistance. However, the strength of its anti-corrosion ability changes with the change of the chemical composition of the steel itself, the state of mutual addition, the use conditions and the type of environmental media. Such as 304 steel pipe, in a dry and clean environment, has absolutely excellent anti-corrosion ability, but in coastal areas, in the sea fog containing a lot of salt, it will quickly rust; while 316 steel pipe performs well. Therefore, not any kind of stainless steel is corrosion-resistant and rust-free in any environment.

Stainless steel relies on a very thin, strong, dense and stable chromium-rich oxide film (protective film) formed on its surface to prevent oxygen atoms from continuing to penetrate and continue to oxidize, thereby obtaining the ability to resist rust. Once the film is continuously destroyed for some reason, the oxygen atoms in the air or liquid will continue to infiltrate or the iron atoms in the metal will continue to separate out to form loose iron oxide. The metal surface will also be constantly rusted.

There are many forms of damage to this surface film, and the following are more common in daily life:

1. The surface of stainless steel has accumulated dust containing other metal elements or attachments of different types of metal particles. In humid air, the condensed water between the attachments and stainless steel connects them into a micro battery, which initiates an electrochemical reaction , Then the protective film is damaged, which is called electrochemical corrosion.

2. The surface of stainless steel is sticky or attached to organic juices (such as fruits or vegetables, noodle soup, sputum, etc.). In the presence of water and oxygen, organic acids are formed. For a long time, organic acids will corrode the metal surface.

3. The surface of stainless steel adhesion contains acid, alkali, salt substances (such as alkali water for decoration walls, splashed lime water), which will cause local corrosion.

4. In polluted air (such as the atmosphere containing a lot of sulfide, carbon oxide, and nitrogen oxide), the surface of stainless steel encounters condensed water, which will form sulfuric acid, nitric acid, and acetic acid liquid spots, causing chemical corrosion.

How to ensure that the metal surface is permanently bright and not corroded:

The above conditions can cause damage to the protective film on the stainless steel surface and cause rust. Therefore, in order to ensure that the metal surface is permanently bright and not corroded, we recommend:

1. The surface of decorative stainless steel must be cleaned and scrubbed frequently to remove attachments and eliminate external factors that cause rust.

2. 316 stainless steel is recommended for coastal areas, because 316 is resistant to seawater corrosion.

3. The chemical composition of some stainless steel pipes on the market cannot meet the corresponding national standards and cannot meet the material requirements of 304. Therefore, rust will also be caused, which requires users to carefully choose products from reputable suppliers.

Stainless steel is also magnetic

People often use magnets to adsorb stainless steel to verify its quality and authenticity. If it is not adsorbed and non-magnetic, it is considered good; if it is magnetic, it is considered a counterfeit. In fact, this is an extremely one-sided and wrong method of identification.

Types of stainless steel

There are many types of stainless steel, which can be divided into several categories according to the organizational structure at room temperature:

1. Austenite type: such as 201, 202, 301, 304, 316, etc.;

2. Martensite or ferrite type: such as 430, 420, 410, etc.;

Austenite is non-magnetic or weakly magnetic, and martensite or ferrite is magnetic.

The stainless steel usually used as decorative tube sheet is mostly austenitic 304 material. Generally speaking, it is non-magnetic or weak magnetic. However, due to chemical composition fluctuations or different processing conditions caused by smelting, it may also be magnetic, but it cannot be considered as a counterfeit or unqualified. What is the reason?

As mentioned above, austenite is non-magnetic or weakly magnetic, while martensite or ferrite is magnetic.

Due to component segregation or improper heat treatment during smelting, a small amount of martensite or ferrite in austenitic 304 stainless steel will result. In this way, 304 stainless steel will have weak magnetic properties.

In addition, after 304 stainless steel component is cold worked, the structure will also be transformed into martensite. The greater the degree of cold working deformation, the more martensite transformation and the greater the magnetic properties of the steel. Like a batch of steel, produced into a Φ76 tube, it has no obvious magnetic induction; Produced into a Φ9.5 tube, the magnetic induction is more obvious due to the larger bending deformation; Produced into a square rectangular tube, because the amount of deformation is larger than that of a round tube, especially in the corners, the deformation is more intense and the magnetism is more obvious.

In order to completely eliminate the magnetic properties of 304 steel caused by the above-mentioned reasons, high-temperature solution treatment can be used to restore and stabilize the austenite structure, thereby eliminating the magnetic properties.

In particular, the magnetism of 304 stainless steel caused by the above reasons is not at the same level as the magnetism of other materials, such as 430 and carbon steel. That is to say, the magnetism of 304 steel always shows weak magnetism.

This tells us that if stainless steel is weakly magnetic or not magnetic at all, it should be judged as 304 or 316 material; if it is the same as carbon steel, it shows strong magnetism, because it is judged as not 304 material.

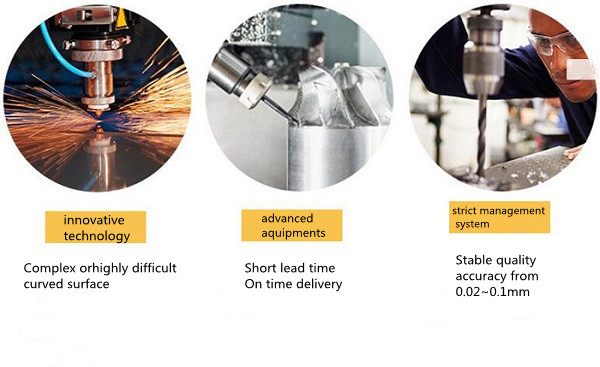

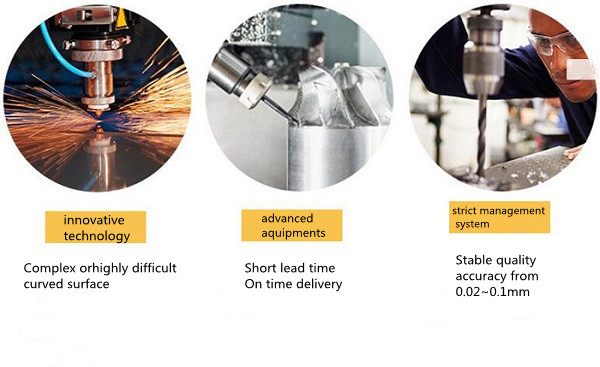

Yejia Precision Machinery Co., Ltd. specializes in CNC machining components/milling parts/grinding parts/welding parts/assembly and other precision parts processing services.

Welcome to contact Janice for more information: sales2@yejiavi.com