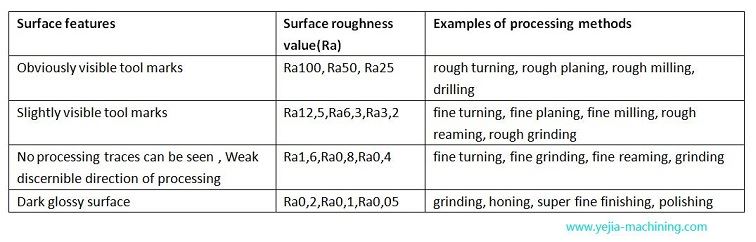

The concept of surface roughness

Surface roughness is a kind of microscopic geometric shape error, which refers to the microscopic geometric shape characteristics composed of small spacing and peaks and valleys on the processed surface of the part, and is used to evaluate the size of the surface roughness parameter.

1) Ra: arithmetic mean deviation of contour

2) Ry: Ten-point height of microscopic unevenness

3) Rz: Maximum profile height

Generally, the height parameter Ra is commonly used, and Ra can also be omitted when marking the surface roughness code.

If the other two evaluation parameters are used, Rz or Ry must be indicated

Ra is generally measured with an electric profiler.

Because the concept of Ra is more intuitive and has a lot of information reflecting the contour, it is widely used.

The common parameter value range of Ra is 0.025~6.3μm.

Yejia precision machining provide CNC turning parts machining service, welcome to contact Miss Janice:

E-mail: sales2@yejiavi.com